Everything you need to know about heat presses

Flat heat presses, mug heat presses, cap heat presses, universal heat presses and calanders – which one should you choose?

What is a heat press?

(Are you already familiar with it? Jump to the next section!)

These devices are used in various transfer printing techniques both in the textile industry – for printing and labeling T-shirts, work clothes and fashion clothing products – and in the production of unique gifts and promotional items. They provide high temperature and consistent pressure, creating suitable conditions for durable print quality.

„I already have an iron. Can I use that for transfer printing?"

We get this question a lot from customers who are new to the industry: could a regular iron be used to iron the printed transfer paper just to get started.

The answer: No! Only a heat press!

Would you like to produce for yourself as a hobby or to sell the printed products? If it's the latter, you can't start without investing in a heat press. Forget the iron! Why? The iron is not capable of even and consistent pressure, as it has to be pressed and moved on the surface by hand. Irons have a small heated surface, while that of a flat heat press is approx. 5-10 time bigger. In addition, the temperature can only be adjusted with a rotary knob and primarily based on the textile material and not on the basis of temperature.

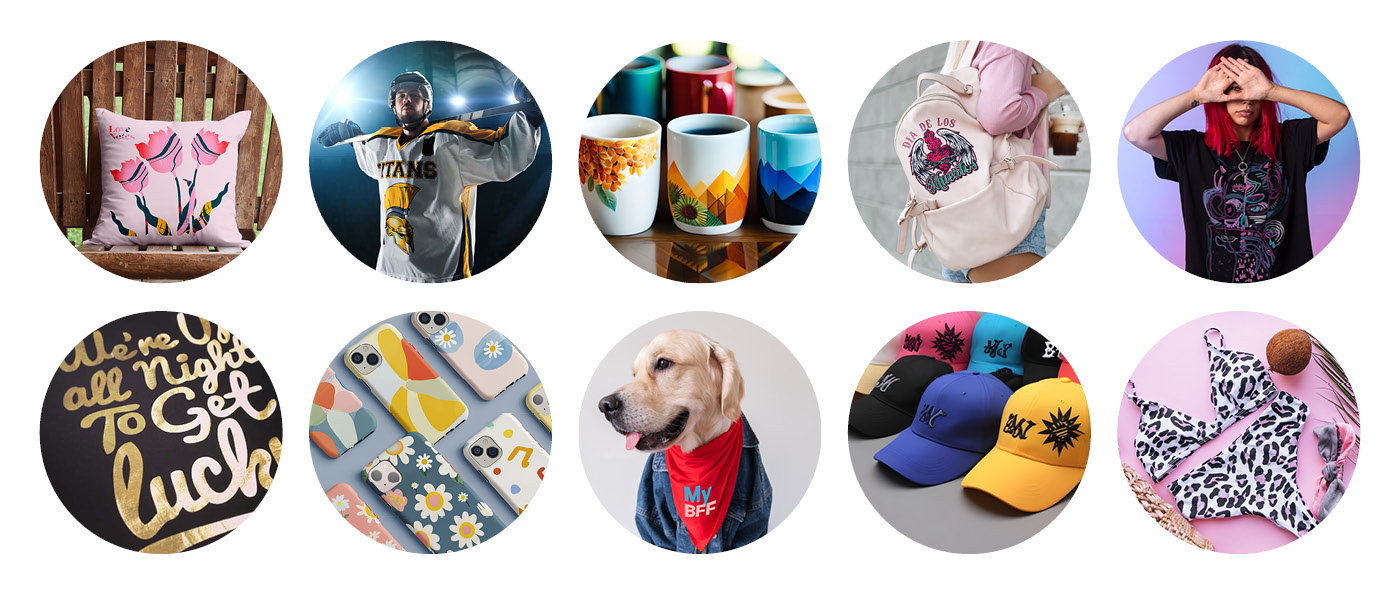

Thousands of possibilities!

The market of textile printing, T-Shirt printing and printing of unique gifts is constantly growing! Don't use your heat press only for a product-specific application!

The most popular area of use is clearly sublimation printing. The biggest advantage of photo sublimation printing is that you can produce countless types of unique gift or promotional items with this technology even in a small workshop or at home without special training, and with minimal investment.

With the sublimation technique, you can only print on polyester textiles or pretreated solid objects. If you want to print on cotton textiles and uncoated objects, you should use transfer papers that can be printed with laser printers and ironed on T-Shirts, other textiles and some types even on hard surfaces. With this technique, you can create photo-quality and machine-washable printed unique items.

If your goal is simply to iron single-color texts, logos and ohter designs to sport jerseys, work attire and T-Shirts, cuttable heat transfer films are the ideal choice for you to succeed in fashion-, sportswear- and workwear segments.

But if your goal is industrial volume T-Shirt printing, DTF printing, which is cost-effective even in smaller quantity uniqe T-Shirt printing but at the same time it produces high quality prints like screen printing. With this technique you can create durable and flexible printed surfaces on almost any types of textile materials.

What are your choices when it comes to heat presses?

The type of the heat press you need to choose depends on the kind of unique product you want to produce with it.

Flat heat presses

This is the primary tool for all T-Shirt printing shops. Its name speaks for itself: it is a tool for fixing ink or ironing transfer papers and foils on flat objects. Screen printing shops use them as well for inks that need to be fixed on the surface of the textile by contact heat.

For entry-level production our cost-efficient BASIC heat presses are adequate, but if you're looking at high-volume printing, choose one of our PRO heat presses like SD-PRO or Galaxy with the capacity and size right for your needs. For our industrial customers we highly recommend our high capacity, premium SEFA heat presses.

Manual or pneumatic heat press? Both types are suitable for high-quality heat treatment either you use sublimation, laser transfer or screen printing technique. The pneumatic feature gives you a great advantage though: you could set it to an exact level and it will provide you with a consistent pressure. Let's say you've ironded a T-Shirt, then you want to iron a coat, a mouse pad or a wood plaque, you don't need to set the pressure level again and test it. Pneumatic air pressure will always be the same, regardless of the thickness of the object. Another great advantage of a pneumatic flat heat press is that it speeds up the work process, thus increasing productivity.

Mug heat presses

The market of unique mug printing businesses has skyrocketed lately. For this technique you only need an A4 sublimation printer, sublimation ink and sublimation transfer paper. We spared you time of choosing the right types of tools and machines and created SUBLISTART mug sublimation system for this very purpose. A click of a button and the complete system for unique mug printing is yours.

Mug heat presses have a a cylindrical heating pads, so that you could iron the printed transfer paper onto the surface of the mug easily without creasing. You could choose from several types of entry level or high capacity mug heat presses and many types of heating pads to go with them.

Cap heat presses

These machines work on the same principle: they fix the printable design by heat and pressure on the surface of the object. This machine has uniquely shaped, curved base surface and heat platen specifically designed to iron the front of the baseball caps.

Great news! We offer a 2in1 heat press with replaceable plates. Thus you basically get two heat presses for the price of one: a cap heat press and a small – 12×12cm flat heat press for smaller items such as keychains, pocket mirrors or even for ironing small logos on T-Shirts.

Special types of universal heat presses

This type of heat press is mainly useful for sublimation printing on unique gift or promotional products. Due to their rim, plates cannot be heat treated in flat heat presses. Plate press machines are equipped with circular top and bottom trays. The bottom one – where the plate should be placed – is bigger, while top one is smaller to fit the inner part of the plate, so that the rim stays free from pressure.The majority of our customers don't even buy it for plates but because of its low energy consumption and 30 second warm-up time which make it and excellent, cost-effective solution for smaller products.

| Hint: Do you want to print on the whole surface of the plate? Scroll a little further to the section on 3D printers! |

A cheap, entry-level multifunctional solution for startup businesses to print on flat objects, mugs, baseball caps, and plates. A small inconvenience might be though that the plates need to be replaced manually on these “combo” heat presses in order to use them for different types of products.

We recommend them for businesses entering the market of unique sublimation objects or those who want to offer unique products in small quantities as an additional service to their main area of business. They are a safe choice for sublimation printing, but if you want to use it for special type, two-layer transfer papers or screen printing, we highly recommend to test them first in our showroom.

When it comes to creative, unique giftmaking, what comes to your mind? Sublimation mugs, mouse pads and T-Shirts? Think further! Only with a 3D vacuum heat press will you be able to keep up with the latest trends of unique gift making.* The versatility of vacuum heat presses comes from the technology: they can press the printed sublimation paper even on curved and special shaped surfaces. With suitable silicone wraps, you can use these heat presses for phone cases, tablet cases, PC mouses and many more types of unique gifts and promotional items. Keep in mind though, that you will need to buy suitable blank sublimation objects. Thankfully our range of 3D heat press compatible sublimation blanks is continuously expanding.

*Keep in mind though that it doesn't mean you will only need this machine. Due to vacuum, it could cause textiles and other soft surfaces to wrinkle, so you will need a flat heat press as well.

Large format heat presses

A special roll-to-roll heat treatment device is essential for large-format roll sublimation printing. Wide format heat presses has two main types based on whether they are designed for direct textil printing or sublimation printing with transfer paper.

- You can fix ink prinited with Direct To Garment technique by a contactless heat treatment machine. festék hőfixálásához kontakt nélküli hőfixáló berendezés szükséges.

- When it comes to ironing sublimation transfer paper on textiles, you will need contact heat by the using a so-called calander. In this case the heated surface also provides the pressure needed for keeping the transfer paper thightly on the surface of the textile for perfectly sharp prints. This technology is suitable for printing flags, banners, textiles to be installed in display products, sportswear, patterned fashion items and textile home decor items. You could iron complete rolls of sublimation textiles in these machines.

Careful! Don't regret your choice!

Before purchasing your heat press, consider:

- Does this machine provide suitable pressure and consistent heat distribution for your preferred technology?

Our answer: Our colleagues will always recommend you the right type for the desired application. You can also test all our machines in our showroom before you make your choise! - General terms and conditions: warranty, service, spare parts supply.

Our answer: We provide 1-year warranty for our machiness with full service. Even after the warranty period, we repair even 5-10 year old machines we sold within a few days.

|

Hint: Forget ebay and second-hand machines you could find on the internet! As soon as a problem appears you will be desperately looking for spare parts on the internet, and – considering the shipping fee –, you will end up paying more in the long run. |

What areas of business can you use them in?

Now let's see what you can use a flat heat press for, just to give you a taste.

- T-Shirt transfer printing: There are Special printable heat transfer papers for both inkjet- and laser printers. You could iron them on T-Shirts and other textiles with a flat heat press.

- DTF T-Shirt printing: In the past few years Direct to Foil transferprinting became without doubt the most popular digital printing technology. A special hot-melt adhesive powder is applied to the transparent DTF PET film, which then needs to be fixed with heat treatment. Finally you can iron this on the surface of the T-Shirt with a heat press. (This doesn't apply to roll-to-roll DTF systems which have a special powdering-heat treatment unit for this task.)

- DTG T-Shirt printing: Although DTF seems to have reduced Direct To Garment printing's popularity immensely, this technology has its own advantages too. To fix the ink you printed directly on the T-Shirt, you will need a heat press.

- Sublimation printing: You could print on countless types of sublimation objects with this technique. Check out our range of printable sublimatin blanks! Besides the heat press, you will also need sublimation printer, sublimation inks and sublimation transfer papers. Learn more about the technique here.

- Cuttable heat transfer films: You could purchase these vinyl foils in rolls or even in 1m long pieces. You will also need a cutting plotter to cut the text or other shapes you want to iron on. You could choose from a great deal of colors and surfaces, even special ones like neon colors, glitter, gold, silver, reflective, glow-in-dark, etc.

- Screen printing: For screen printing shops, we recommend our PRO series or SEFA flat heat presses, which provide excellent heat distribution and stable daily operation.

- Ironing „Hard Surface” transfer papers: You could print on hard objects without special coating – whether it's wood, glass, metal or ceramics – using our transfer papers for hard surfaces. If you'd like to print on colorful objects too, then you will need a white toner OKI or Uninet iColor printer. As always, you can count on us to only provide you systems which produce durable printed objects!